Plastic Repair Services

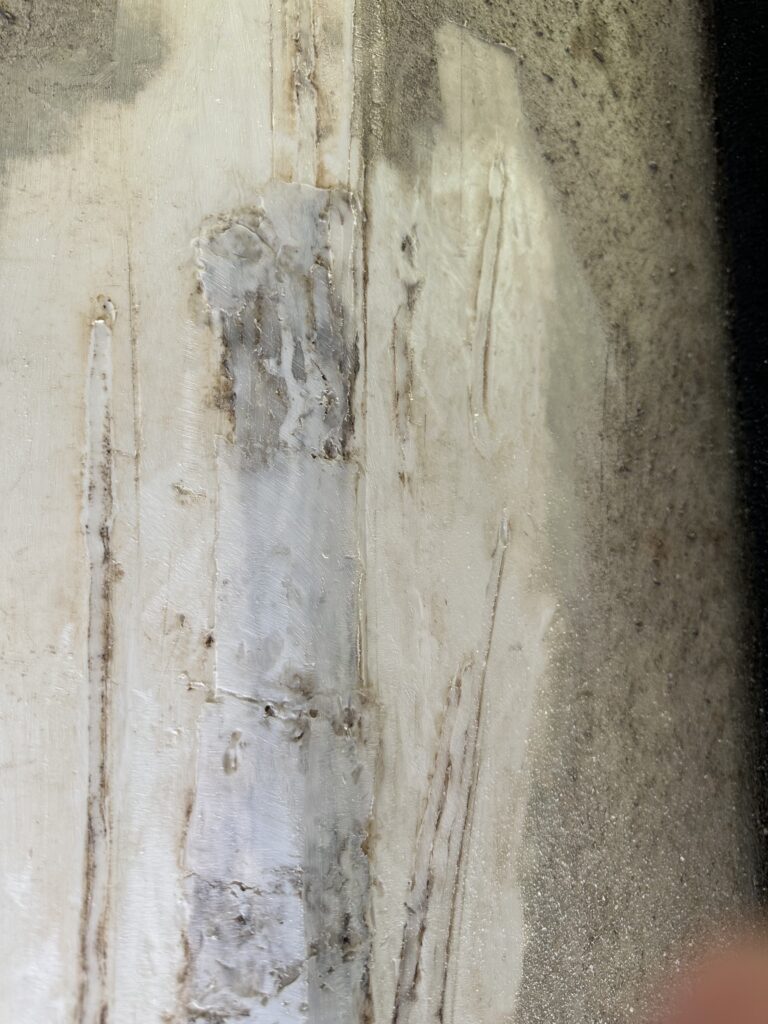

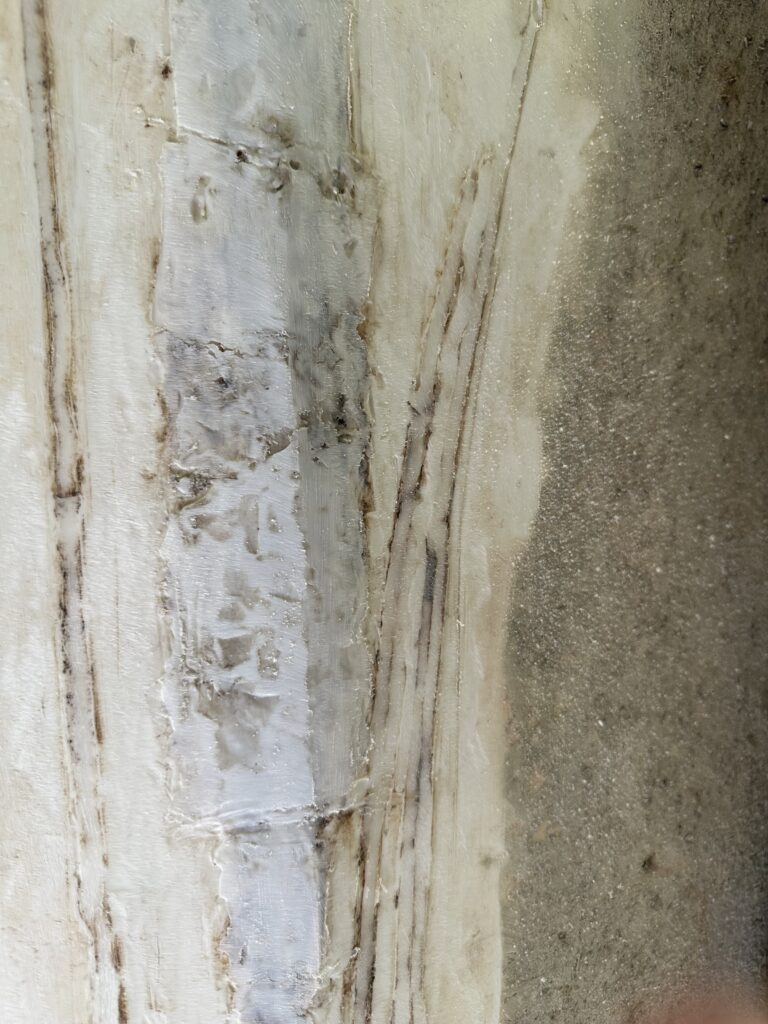

Plastic welding is a process that uses heat or pressure to join plastic materials together, creating strong, durable seams. This technique is commonly used to repair, fabricate, or assemble plastic components in industries like automotive, manufacturing, and construction. Plastic welding methods, such as hot air welding, extrusion welding, and ultrasonic welding, allow for precise control over the bonding process, ensuring high-quality results. Whether for creating custom plastic parts, repairing cracked components, or producing large-scale assemblies, plastic welding offers a reliable, cost-effective solution for creating seamless, long-lasting plastic connections.

Hot Air Welding vs. Plastic Gluing

- Hot Air Welding: This technique uses a stream of heated air to soften the edges of the plastic parts, which are then fused together with a filler material to create a strong, permanent bond. It’s perfect for joining thermoplastic materials and is commonly used in applications such as plastic repairs, fabrication of tanks, and manufacturing plastic components. Hot air welding provides a durable result that restores the structural integrity of plastic items.

- Plastic Gluing: For less-intensive repairs or joining smaller plastic parts, gluing offers a precise, easy solution. High-strength plastic adhesives bond quickly and effectively, creating a solid hold without the need for heat or additional equipment. Gluing is ideal for lightweight repairs, intricate designs, and situations where welding may not be practical.